Caution! Read all safety warnings and instructions!

Read these General Safety Instructions as well as the Instruction Manual carefully and follow all instructions.

To provide increased comfort and support while playing and to prevent injury to you or damage to your instrument, the PIRASTRO KorfkerSpring® must be fitted and used as explained in the instruction manual. The KorfkerSpring could damage your instrument if it loosens or breaks and impacts your instrument, or if it comes off, causing you to lose control of your instrument.

Incorrect use or maintenance could result in physical discomfort, interruptions while playing your instrument or, in rare cases, physical harm.

Excessive force put onto the PIRASTROKorfkerSpring® will cause it to break.

The springs cannot be shaped by bending. Trying to do so will cause them to snap.

Depending on playing style and force used, the springs of the KorfkerSpring may deform over time and if not replaced may break during normal use.

Before every use verify the correct setup and secure attachment of your PIRASTRO KorfkerSpring®, especially after having made adjustments. Refer to the Instruction Manual for details.

Check all parts of your KorfkerSpring, and in particular the spring, for damage, wear and tear before every use. If damaged or worn parts are detected, do not use the KorfkerSpring until these parts have been replaced. Continued use can lead to direct damage to the instrument, instability of your KorfkerSpring or discomfort while playing your instrument.

For maintenance use only Pirastro's original replacement parts.

No liability accepted for inappropriate use.

Introducing the individual parts

The chin plate of the KorfkerSpring, crafted from hardened Swiss maple, can be precisely adjusted in three axes and positioned freely along the mounting slot. Depending on personal preference it can be used free moving or secured.

The mounting piece sits between chin plate and spring and is part of a ball joint which enables full three-axis adjustment. It can be positioned freey along the mounting slot.

The springs give the PIRASTRO KorfkerSpring® its unique flexibility. They allow the neck to remain free and provide feedback regarding the forces used during playing. The material of the springs has been carefully formulated to avoid sudden failure under pressure. Instead, if overloaded, the springs will visually deform, indicating that they should be replaced. Significant deformation may either indicate that too much force is being used, or that a lower spring may be a better fit. Players who apply low pressure to the chin plate may never need to replace the spring.

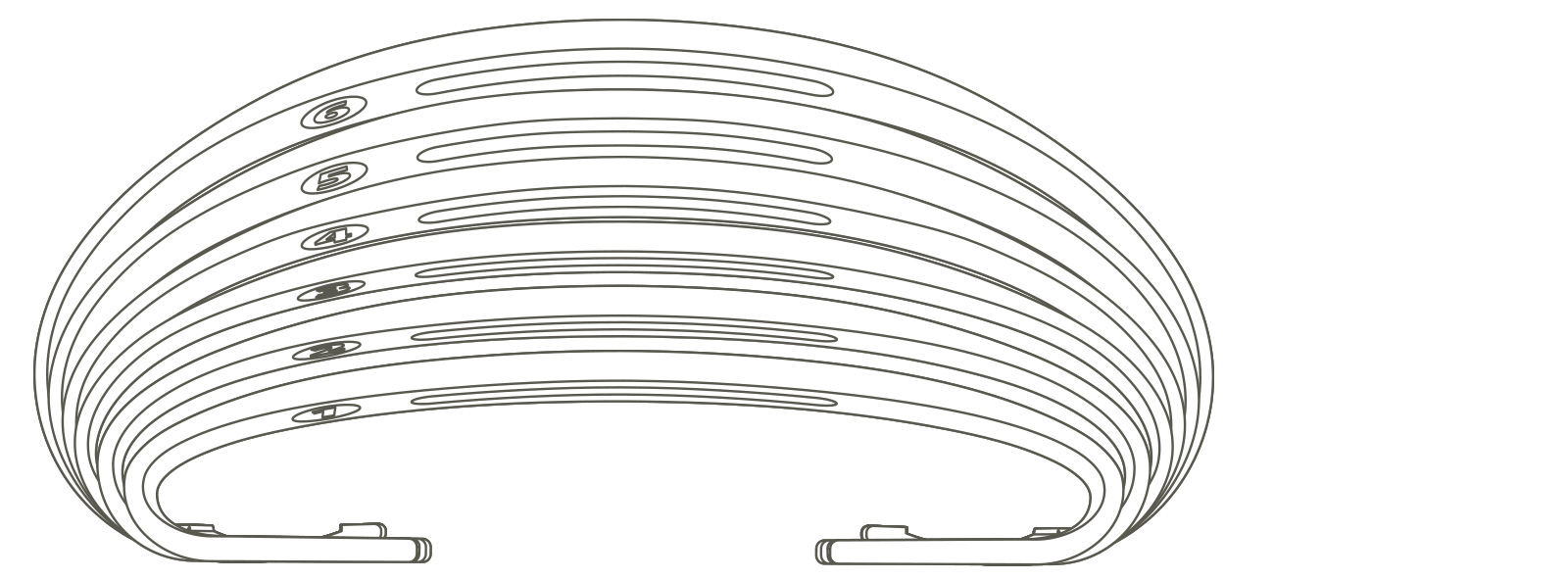

The PIRASTRO KorfkerSpring® comes with six springs, accommodating a height of 25 - 50 mm in steps of 5 mm. Springs 1 and 2, which offer the least flexibility, are typically used to either side of the tailpiece and remain on the instrument. Springs 3, 4, 5, and 6 are more flexible, can be center- or side-mounted, and may be removed if the KorfkerSpring is too high to fit in the instrument’s case.

The clamps connect the various springs to the body of the instrument and, using an extra fine thread, allow very precise adjustment of the clamping force. The instrument’s surface is protected by premium natural cork pads. A thin synthetic film makes them hard-wearing and prevents slipping or sticking to the varnish.

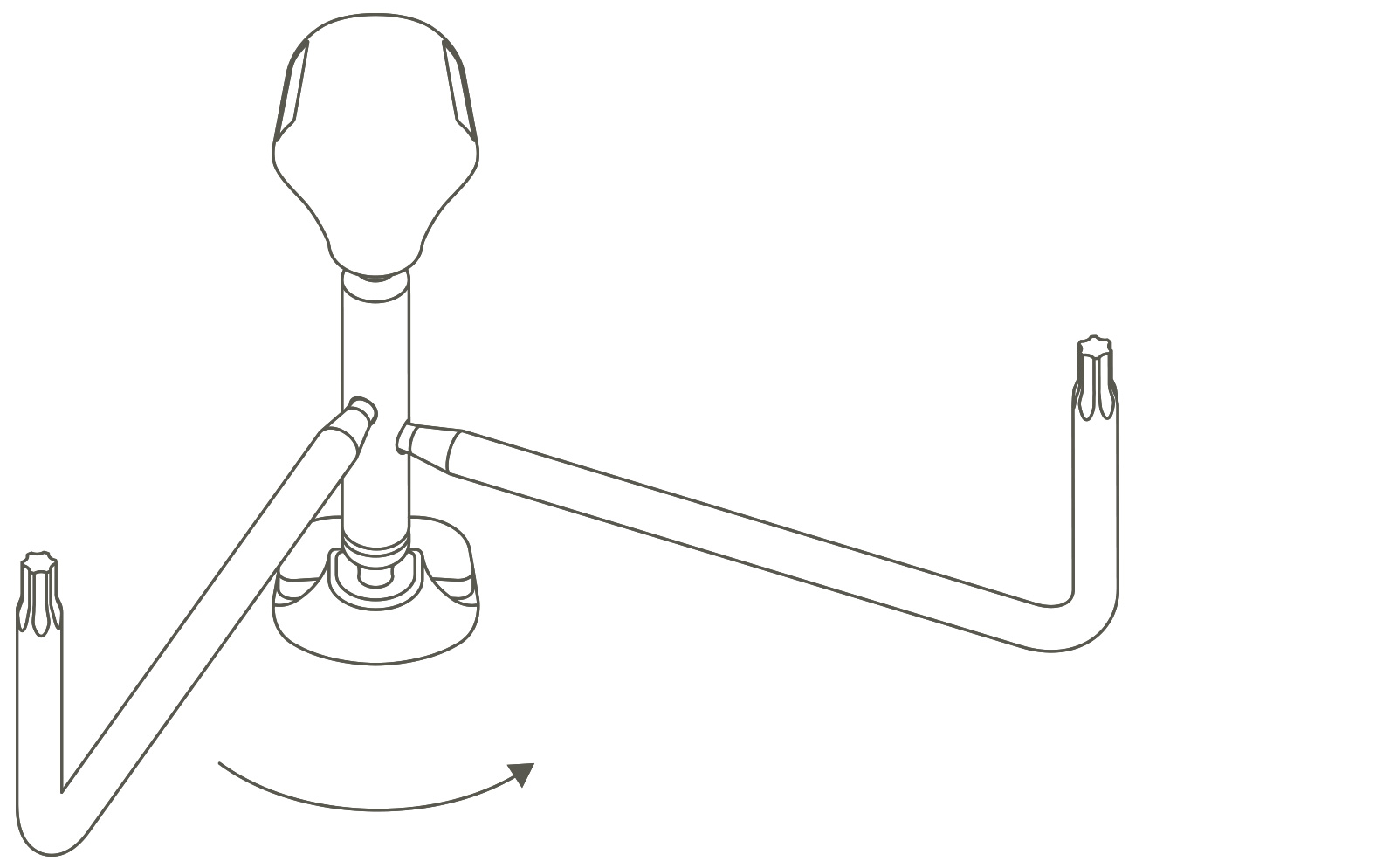

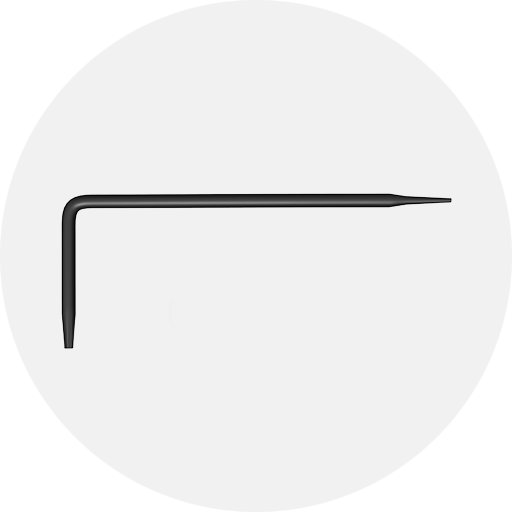

The adjustment key is found in the tool loop of the inner mesh of the protective zipper case which safely stores your KorfkerSpring and its accessories.

Positioning the clamps

To install the KorfkerSpring on a viola, the barrels of the clamps will need to be swapped for the longer ones included in the accessories. Please see the chapter »Swapping the barrels« for details.

Before attaching the clamps to the instrument, determine their correct spacing by inserting the clips of your preferred spring into the upper clamp heads (see »Inserting and Removing the Springs«). Next, position the KorfkerSpring to one side of, or over the tailpiece (see fig. 3 and 4).

When using spring 1 or 2 centred over the tailpiece, position the mounting piece to the left or right of it to avoid contact during compression (see »Positioning the Chin Plate«).

1 Tightening the clamp

2 Maximum cork compression

Now, while the flexibility of the spring allows them to adjust to the shape of the instrument, hold all clamp heads flush with its edge and tighten the clamps with the adjustment key (see fig. 1) until all four cork pads have a secure hold. A day after installation tighten the clamps by half a turn of the barrels to compensate for the compression of the cork pads.

3 Center mounted PIRASTRO KorfkerSpring®

4 Side mounted PIRASTRO KorfkerSpring®

Inserting and removing the springs

SPRINGS 1 AND 2:

To remove or insert springs 1 and 2, always remove the clamps from the instrument first.

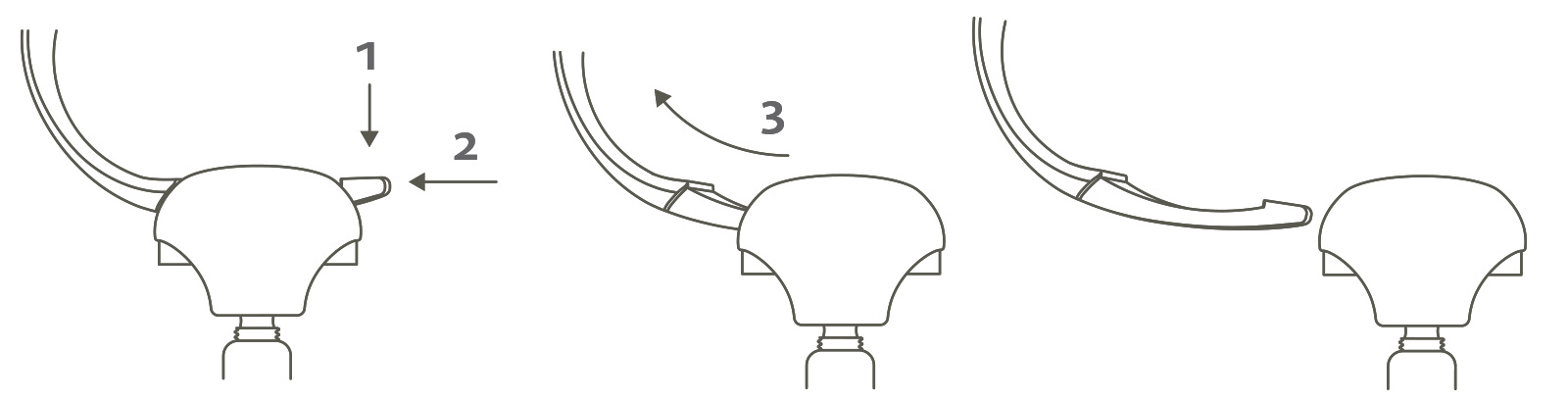

Remove the spring by pushing the clip end at the front of the upper clamp head inwards and back into the clamp (see fig. 5). The clip can now be removed from the clamp head.

5 Removing the clip (spring 1 or 2) from the upper clamp head

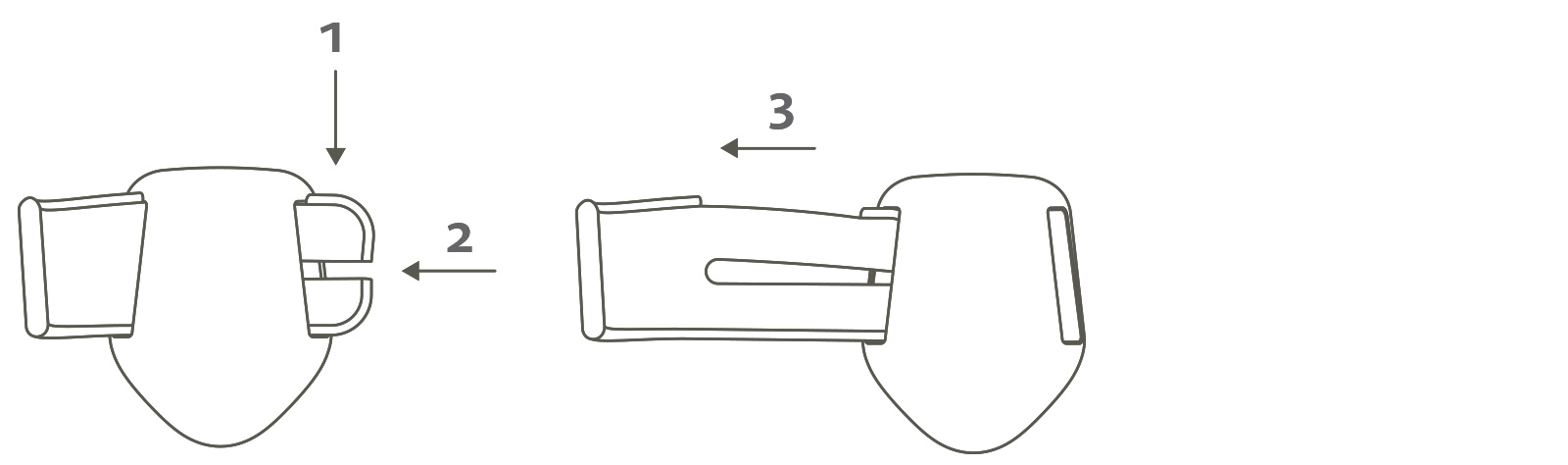

When inserting the clips of springs 1 and 2, ensure they are correctly oriented before pushing them into the slot of the upper clamp head until a click is heard (see fig. 6).

6 Inserting the clip (spring 1 or 2) into the clamp head

SPRINGS 3 TO 6:

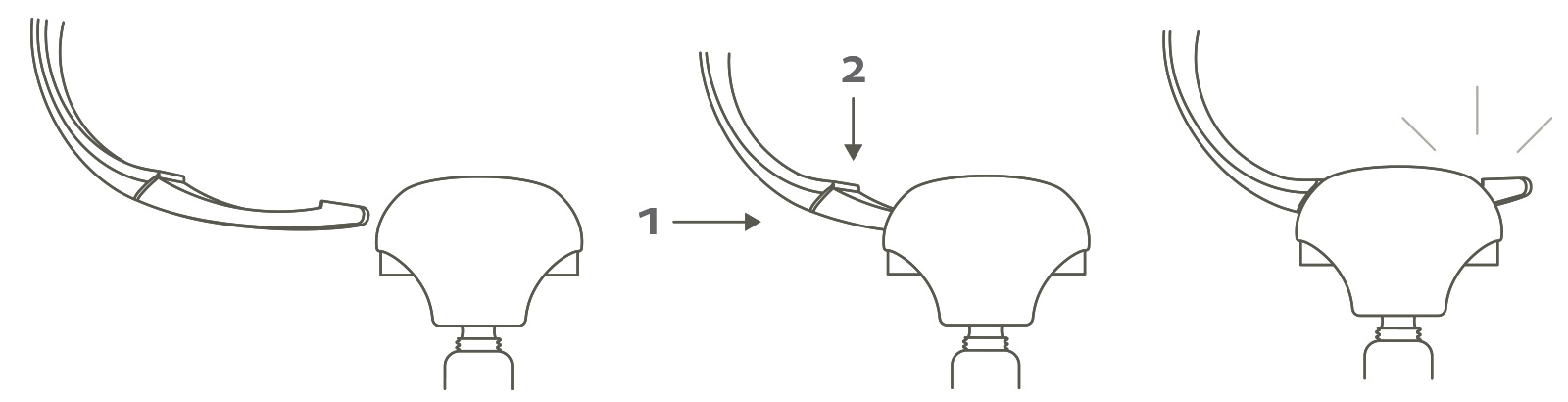

Springs 3, 4, 5 or 6 can be alternated between without removing the clamps from the violin or changing their positions. To remove one of them, press down the small lip protruding through one of the upper clamp heads and push it back into the slot (see fig. 7). Now carefully pull the clip from the slot.

Please take care not to damage your instrument while removing the spring.

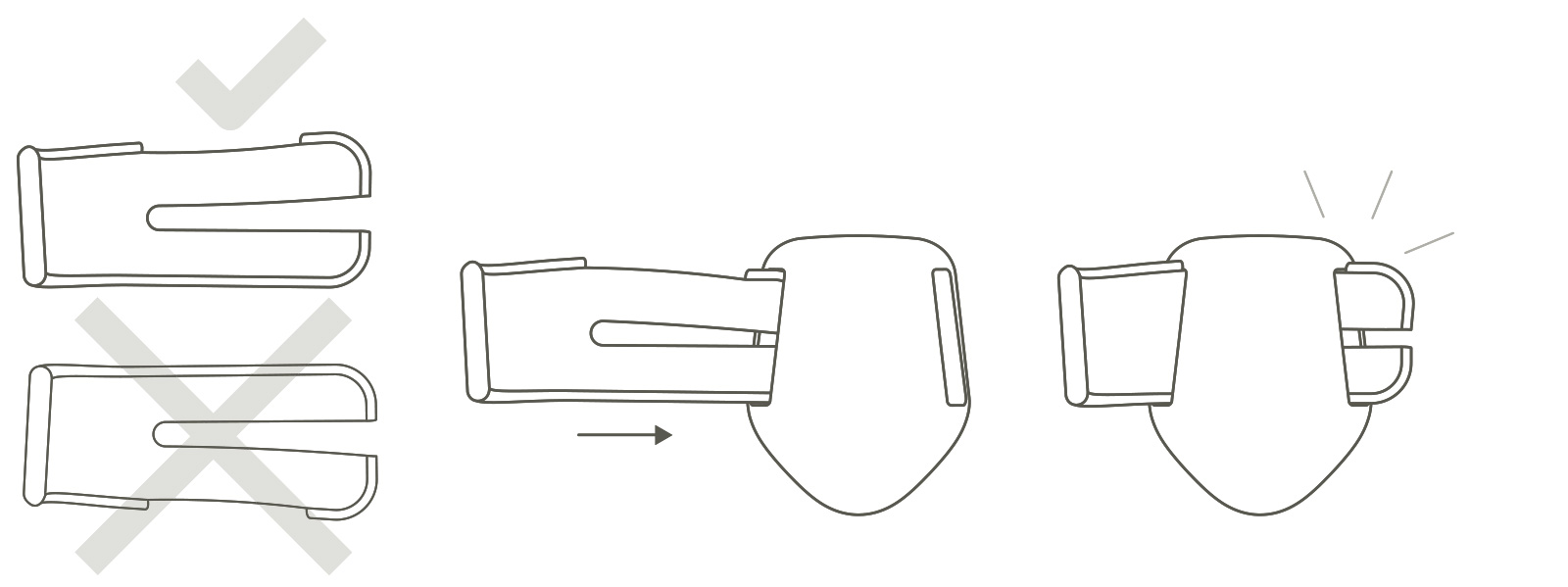

When inserting springs 3 - 6, ensure correct orientation of the

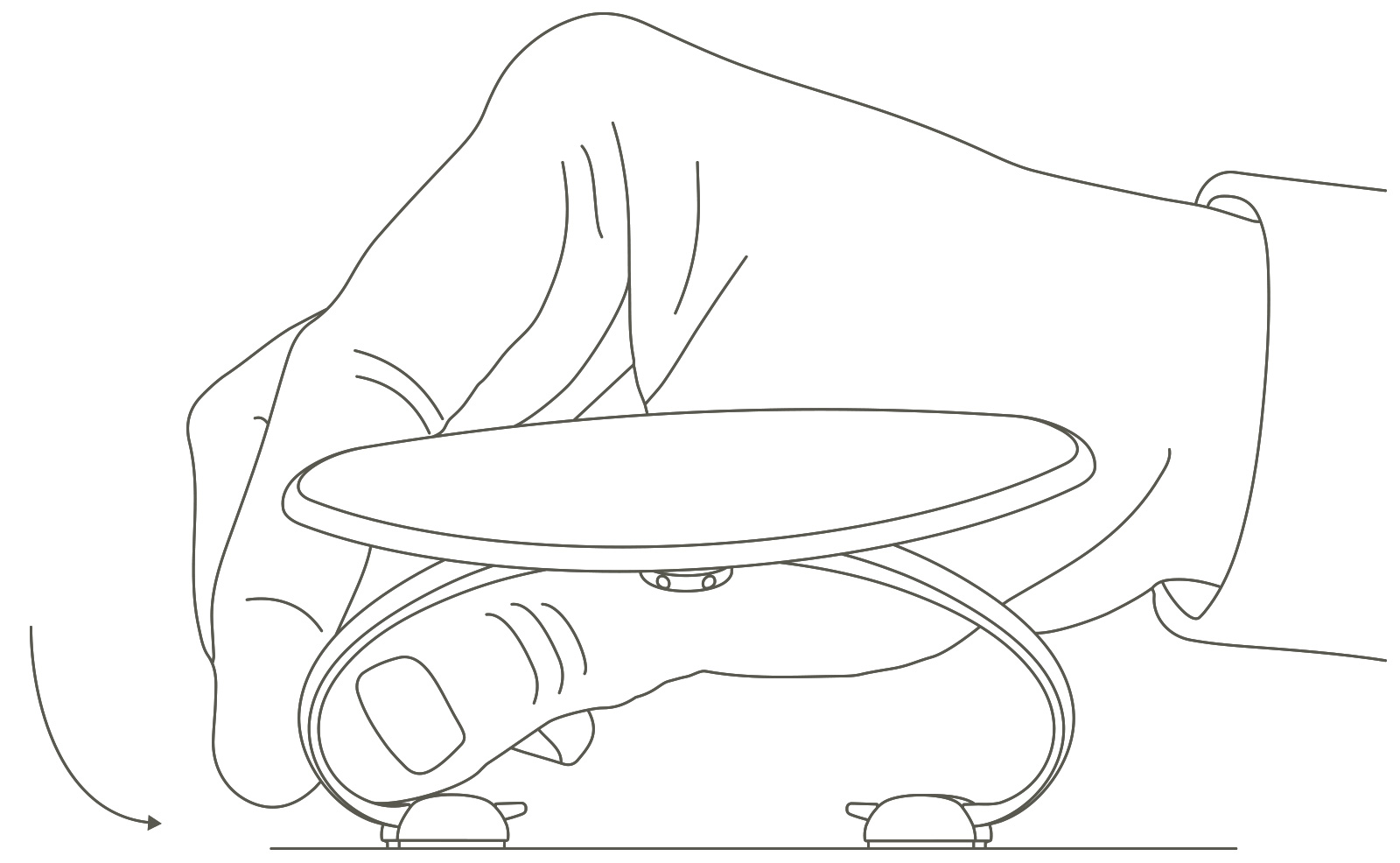

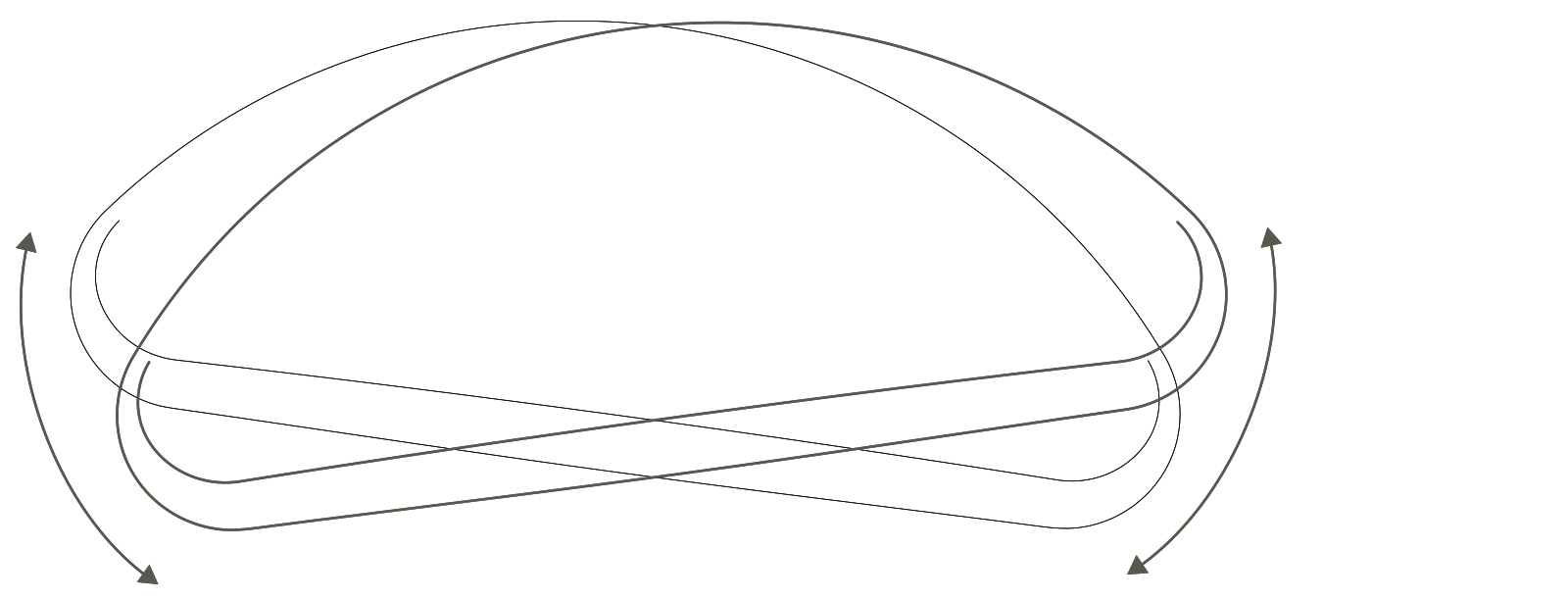

clips as they fit into the clamps in only one way (see fig. 8). Apply gentle downward pressure during insertion (see fig. 9). For best results, use a circular motion (see fig. 10). A click confirms the engagement of the clip.

7 Removing the clip (spring 3 - 6) from the clamp head

8 Correct orientation for inserting the clip (spring 3 - 6)

9 Inserting the clip (spring 3 - 6) into the clamp head

10 Inserting the clip (spring 3 - 6) with a circular motion

Adjusting the height

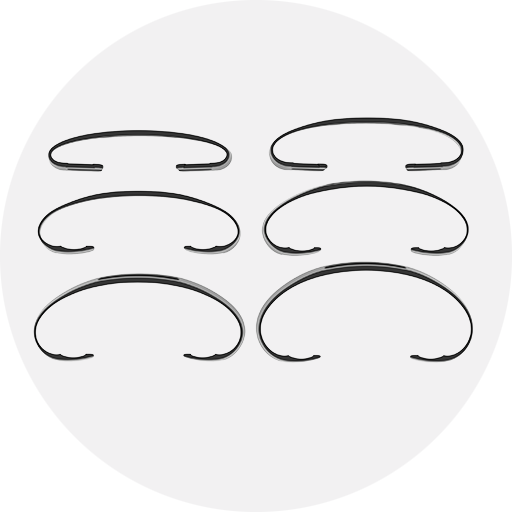

The height of the chin plate can be adjusted in 5mm increments by mounting it onto a higher or lower spring. Spring no. 1 elevates the chin plate to a height of 25 mm, spring no. 6 to 50 mm (see fig. 11). Depending on its pitch or tilt, the effective height can be 3mm higher or lower.

11 Springs no. 1 - 6

To use the PIRASTRO KorfkerSpring® comfortably – with the neck healthily elongated and the violin resting on the collarbone – there should be approximately 1 cm of free space between the chin plate and the jaw or chin. To balance the violin, simply nod the chin towards the chin plate. Avoid reaching the chin over the plate, as this can lead to neck strain or injury.

Over time, the PIRASTRO KorfkerSpring® allows the neck to lengthen, so a higher spring may become necessary.

Changing the spring

Springs 3–6 can be alternated between without removing the clamps from the violin or changing their positions. Springs 1 and 2, however, cannot be removed without first removing the clamps and each require a slightly different clamp position.

Loosen the clamps if necessary, then remove the chin plate and spring assembly from the clamp heads (see fig. 5 and 7 and »Inserting and removing the springs«). Next

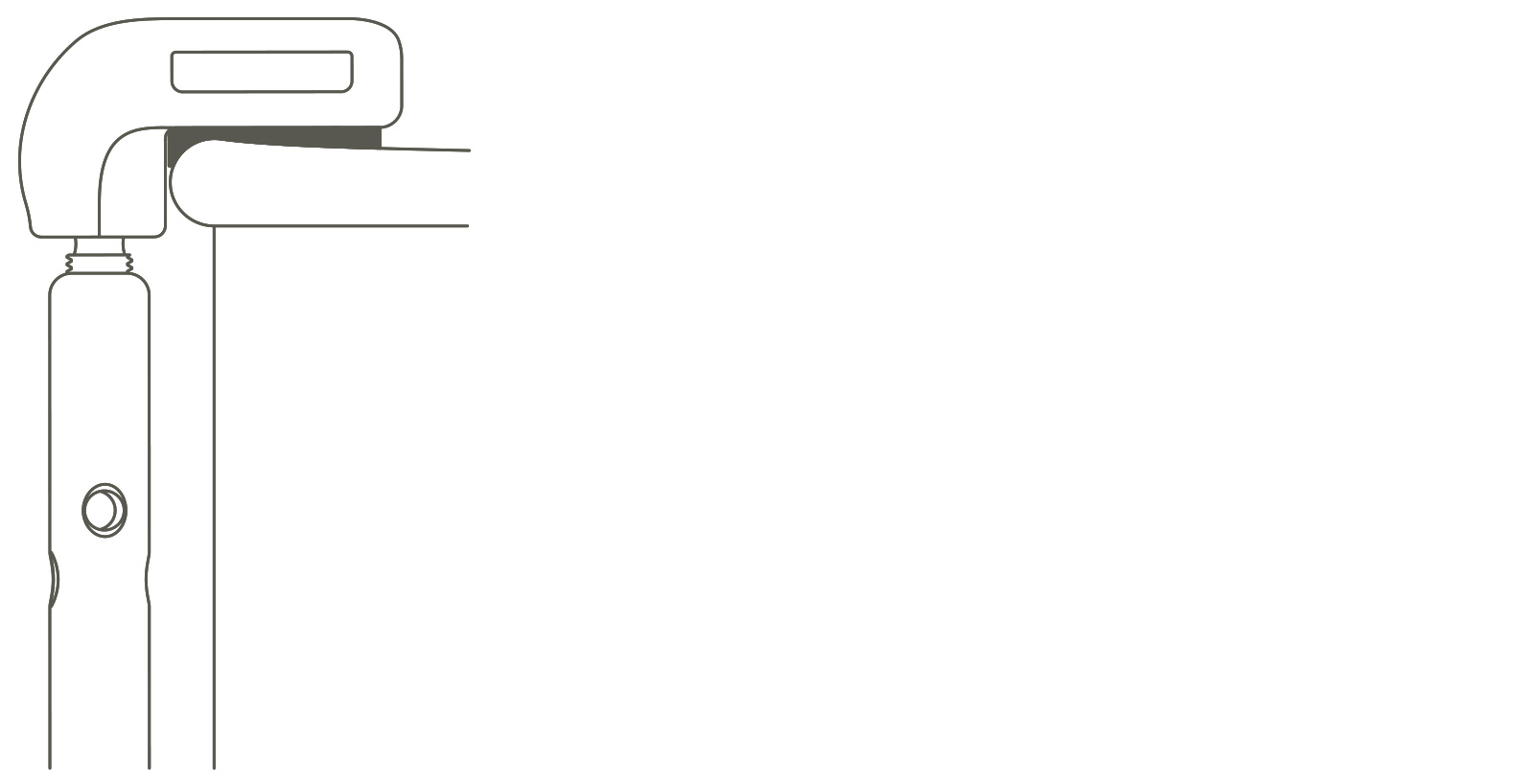

loosen the fastening disk with the adjustment key (see fig. 12).

12 Loosening the fastening disk

Once it rotates easily, loosen the fastening disk further by hand until there is a gap of at least 1 mm between it and the mounting piece (see fig. 13).

13 Loosening the fastening disk and press upwards

While holding the spring, use the thumb to press the mounting disk firmly toward the mounting piece until it touches. A click may be heard. Remove the fastening disk and separate the chin plate and its screw from the mounting piece (see fig. 14).

14 Separating the chin plate from the mounting piece

Now swap the mounting piece over to the chosen spring (see fig. 15-17) while observing its correct orientation.

15 Sliding the mounting piece off the spring

16 Sliding the mounting piece onto the spring 17 Side view

18 Aligning the ovals 19 Inserting the chin plate screw

20 Face rounded edge down

Aligning its oval section with the corresponding opening in the mounting piece (see fig. 18), insert the chin plate screw (see fig. 19) and – with its rounded edge facing downwards (see fig. 20) – screw the fastening disk back on by hand.

Next, proceed to »Positioning the chin plate«.

Positioning the chin plate

In the process of assembly and before tightening the fastening disk any further, it will be possible to position the mounting piece along the mounting slot.

If the mounting piece does not move freely within the mounting slot, loosen the fastening disk with the adjustment key (see fig. 12), then continue by hand until there is a gap of at least 1 mm between fastening disk and mounting piece (see fig. 13). While holding the spring, use the thumb to press the mounting disk firmly toward the mounting piece until it touches. A click may be heard.

Do not slide the mounting piece along the mounting slot with force, as this will damage the slot.

12 Loosening the fastening disk

13 Loosening the fastening disk and press upwards

Once a good position within the mounting slot has been found, tighten the fastening disk first by hand, then with the adjustment key until the chin plate has been lightly secured.

21 Do not slide with force

22 Rotating the chin plate

To adjust the rotation, roll and pitch of the chin plate,

loosen the fastening disk until the chin plate can move freely on the mounting piece but experiences a degree of friction. It can now be rotated and rolled to match the jaw line and preferred holding angle. It can also be pitched forward or backward to accentuate or minimize its ridge. Alternatively, you can find the ideal rotation, roll and pitch by placing the chin plate under your jaw and letting it adjust by itself before securing it.

23 Rolling the chin plate sideways

24 Pitching the chin plate forward or backward

After making final adjustments, tighten the fastening disk by 2-3 holes. When in doubt, check if the desired resistance has already been reached. If the chin plate moves during playing, only tighten the fastening disk further by small increments.

Some players may choose to allow the chin plate to move freely and follow the natural movements of the head. This freedom of movement can be subtly adjusted by tightening or loosening the fastening disk, where small adjustments may already have the desired effect.

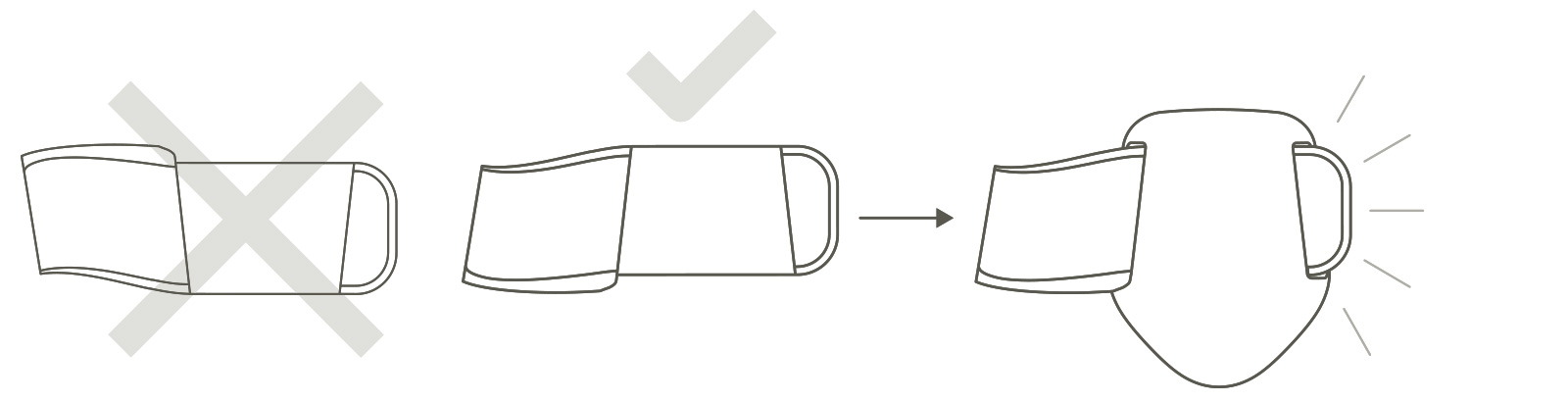

Safely storing chin plate and spring

If you prefer to use springs 3, 4, 5, or 6 and the KorfkerSpring is too tall for your instrument case when fitted, you can remove the chin plate and spring assembly and store it in the supplied protective case. To do so, place the assembly in the shallow tray of the open protective case, with the straight edge of the chin plate facing downward and the spring pointing toward the center. The magnet integrated into the black holder engages with the end of the chin plate screw and prevents the assembly from falling out unintentionally when the protective zipper case is opened.

Spring service life

The uniquely formulated material of the springs exhibits a break-in period during which the spring adapts to the user’s playing style. Applying substantial force to the chin plate will cause more initial deformation to the spring than more relaxed playing styles. Under continued high pressure, deformation will gradually increase until the spring needs replacement.

As the user learns to reduce the force used during playing, the service life of new springs increases. Players applying low pressure to the chin plate may never need to replace the spring.

Significant and rapid deformation may also indicate that the spring was chosen too high, in which case replacing it with the number below is advised.

During normal use, the spring compresses between 0 and 10

mm indicating an applied pressure of 0 – 3.5 kg. If the spring is continuously compressed beyond 15 mm (over 4.5 kg), permanent deformation will occur. The section of the spring where the mounting piece is positioned will start to flatten. With continued use it may then start to bottom out (see fig. 27), at which stage the spring needs to be replaced.

27 Deformed spring

All springs are available as replacement parts.

Chin Plate

After use, we advise wiping the chin plate with a clean, dry, cloth. If the surface needs deeper cleaning, use rubbing

alcohol. To maintain its original look and feel, occasionally

re-oil the chin plate with Pirastro’s string cleaning oil, almond oil, or coconut oil.

If you have particular skin allergies, please seek medical advice on the best oil to use.

The almond oil originally used to oil the chin plate can be removed with high percentage alcohol.

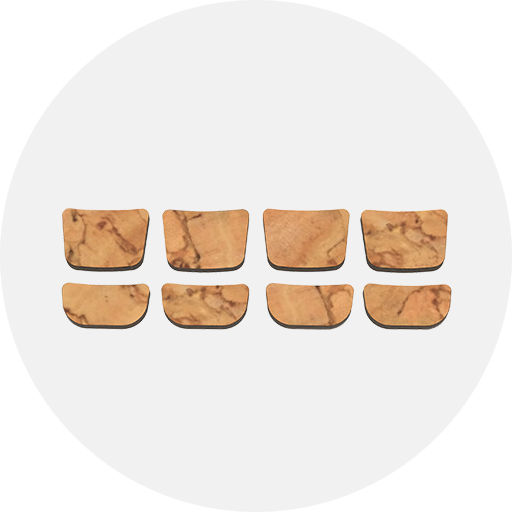

Cork Pads

The cork pads are coated with a resilient, non-slip film. For optimal function, it must be free of dust and grease and therefore should not be touched with the fingers. To ensure a pad is free of dust, cover its full surface with a strip of sellotape and subsequently remove it. This will leave behind a clean and shiny surface.

To degrease the cork pads we advise using a soft cloth and rubbing alcohol.

Ensure the surface of the pads is completely dry and clean before fitting them to the instrument.

If the cork pads are worn, replacements can be ordered. It is recommended that new cork pads are fitted by an experienced luthier. To do so, first remove the worn pads from the clamp head, along with any remaining cork and glue.

We recommend using superglue – preferably gel – for attaching the new cork pads. Follow the manufacturer’s warnings and usage instructions when handling the glue. Also, note that the upper and lower clamp jaws have different pad shapes and that the cork pads should not be glued to the clamp heads on the coated side. If still present, remove the protective films from the cork pads before assembling the clamps.

Spring No. 1

PIRASTRO KorfkerSpring®

Art. No. 705402

Spring No. 2

PIRASTRO KorfkerSpring®

Art. No. 705403

Spring No. 3

PIRASTRO KorfkerSpring®

Art. No. 705404

Spring No. 4

PIRASTRO KorfkerSpring®

Art. No. 705405

Spring No. 5

PIRASTRO KorfkerSpring®

Art. No. 705406

Spring No. 6

PIRASTRO KorfkerSpring®

Art. No. 705407

Spring No. 1-6 Set

PIRASTRO KorfkerSpring®

Art. No. 705401

Fastening disk

PIRASTRO KorfkerSpring®

Art. No. 705409

Cork pads, 2x 4 pcs.

PIRASTRO KorfkerSpring®

Art. No. 705408

Adjustment key

PIRASTRO KorfkerSpring®

Art. No. 705400